Optimize your supercar’s performance by focusing on aerodynamics. The shape of a vehicle significantly influences its speed, stability, and fuel efficiency. A streamlined design reduces drag, allowing supercars to slice through air with minimal resistance. For instance, many modern supercars utilize a low front end and a tapered rear to enhance airflow and minimize turbulence.

Consider active aerodynamic components like adjustable spoilers and air intakes. These features actively respond to speed and driving conditions, enhancing downforce and grip on the road. Enhanced downforce is essential for cornering at high speeds, ensuring that tires maintain optimal contact with the pavement.

Another key factor is weight distribution. Properly balanced aerodynamics prevent lift that can destabilize a vehicle at high speeds. Look for supercars that prioritize a low center of gravity, which improves handling and performance. The integration of lightweight materials, such as carbon fiber, can contribute to both improved aerodynamics and reduced overall weight, further boosting performance.

Testing aerodynamics through wind tunnel simulations provides valuable insights. This practice allows engineers to refine designs before production, ensuring each supercar achieves peak performance. By prioritizing aerodynamics, you create a supercar that not only looks stunning but also performs exceptionally on the track.

Understanding Drag Coefficient in Supercars

Focus on optimizing the drag coefficient (Cd) in supercars to enhance performance. The drag coefficient measures how much aerodynamic drag a vehicle experiences, directly impacting acceleration, top speed, and fuel efficiency. A lower Cd means less air resistance, allowing for better performance.

For supercars, the ideal drag coefficient usually falls between 0.25 and 0.30. Many high-performance models like the Bugatti Chiron and the Tesla Roadster achieve Cd values in this range, demonstrating how crucial aerodynamics are in design. Car manufacturers invest in extensive wind tunnel testing to refine shapes and surfaces that minimize drag while maintaining stability at high speeds.

To optimize a supercar’s drag coefficient, consider the following key aspects:

| Design Aspect | Description |

|---|---|

| Body Shape | Smooth, rounded shapes reduce turbulence. Low, wide forms enhance airflow around the vehicle. |

| Front Grille Design | Utilize active grille shutters that close at high speeds to reduce drag. A properly designed grille should balance cooling needs and airflow. |

| Rear Spoilers | Adjustable rear spoilers can manage downforce and drag based on speed, allowing maximum efficiency across different driving conditions. |

| Underbody Design | A flat underbody helps streamline airflow, reducing turbulence and drag, thus benefiting high-speed performance. |

| Wheel Design | Wheel covers and aerodynamic wheel designs can significantly reduce drag caused by turbulent airflow around the wheels. |

Supercars often feature innovative materials that further improve aerodynamics. Carbon fiber and lightweight metals decrease mass while maintaining structural integrity. Lightweight designs contribute to better acceleration and performance without compromising stability.

Monitoring real-world performance data is equally essential. Use telemetry systems to gather information on drag coefficients during tests. Adjustments based on actual conditions can lead to structured improvements. By focusing on these aspects, supercars can achieve optimal aerodynamic efficiency, enhancing their overall driving experience and capabilities.

The Role of Downforce in Cornering Stability

To achieve optimal cornering stability, supercars must maximize downforce. Downforce presses the vehicle down onto the track, increasing tire grip and allowing for higher cornering speeds. This crucial aerodynamic force is generated primarily through front and rear wings, diffusers, and body shape.

Adjustable aerodynamic components offer flexibility for varying track conditions. For instance, increasing front downforce can improve steering response, while enhancing rear downforce stabilizes the car during high-speed turns. Adjustments should consider the track layout and weather conditions. On a slippery surface, balanced downforce prevents understeer and oversteer, enabling more precise handling.

Quantifying downforce is essential for engineering a competitive edge. Supercars can produce downforce figures ranging from 1000 to over 3000 pounds at high speeds. This figure translates directly into enhanced tire contact with the road, substantially reducing lap times. Wind tunnel testing and CFD simulations ensure that designers fine-tune aerodynamic elements before hitting the track.

Maintaining a suitable angle of attack for wings and splitters is key. While a steeper angle increases downforce, it can also increase drag. Managing this balance allows for better acceleration out of corners. Many teams employ active aerodynamics, which adjust during varying driving conditions, optimizing performance across different scenarios.

Lastly, driver feedback plays a crucial role. Experienced drivers can fine-tune their inputs based on the downforce characteristics of their vehicle. Understanding how the car reacts with varying downforce levels helps in improving cornering techniques, which ultimately enhances overall performance. Prioritizing downforce generates a powerful synergy between aerodynamics, tire performance, and driver control, significantly influencing race outcomes.

How Airflow Impacts Cooling Systems in High-Performance Vehicles

Optimize the airflow around your supercar’s cooling system to maximize its performance. Proper airflow reduces engine temperatures, enhances cooling efficiency, and extends component lifespan. Design features such as front air intakes and hood vents are critical. They facilitate airflow directly over radiators and oil coolers.

Utilizing underbody diffusers can further improve airflow management. These elements create low-pressure zones, pulling hot air away from the engine bay. Regularly inspect and maintain these components to ensure unobstructed airflow; even small debris can disrupt the system’s efficiency. Additionally, implement active cooling technologies. Adjustable vents or fans that react to temperature changes can dynamically control airflow, enhancing cooling when needed.

Test aerodynamic shapes for your vehicle. Wind tunnel simulations help identify airflow patterns that maximize cooling without compromising speed. Enhanced designs promote laminar flow, reducing turbulence and heat soak in heat-sensitive areas.

Consider the materials used in your cooling system. Lightweight materials with high thermal conductivity, such as aluminum or composites, improve heat dissipation while minimizing weight. This choice contributes to better handling and acceleration dynamics.

Monitor coolant temperatures routinely. An optimal temperature range ensures the reliability and performance of engine components. Use real-time data from sensors to adjust cooling strategies on-the-fly, ensuring that the system responds effectively during high-performance driving.

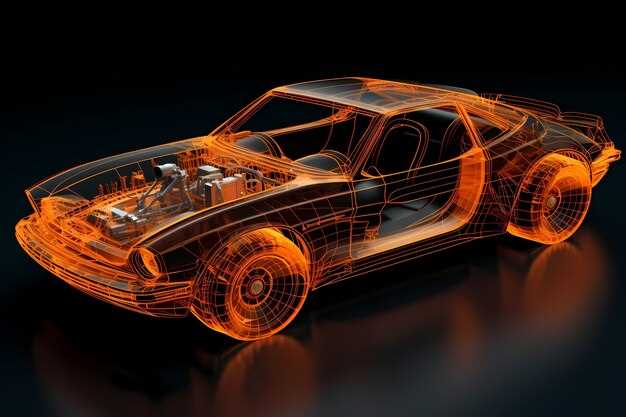

Design Innovations for Optimal Aerodynamics in Supercars

Incorporating active aerodynamics into supercar design significantly enhances downforce and reduces drag. Systems that adjust spoilers and air intakes based on speed and driving conditions optimize airflow, helping to maintain stability and improve handling at high speeds.

Utilizing computer-aided design software allows engineers to model airflow around the vehicle accurately. This helps in creating streamlined shapes that minimize air resistance. Brands like Ferrari and McLaren leverage these technologies to refine their silhouettes and ensure every contour serves an aerodynamic purpose.

Materials play a critical role in weight reduction and aerodynamic efficiency. Advanced composites, such as carbon fiber, allow for lighter structures that contribute to faster acceleration and improved fuel efficiency without compromising strength. This weight-saving measure directly impacts how effectively a supercar can slice through air.

Ventilation strategies can also enhance performance. Integrating functional air vents reduces pressure buildup under the car, improving airflow and cooling the brakes. The high-speed airflow helps maintain optimal temperatures, crucial during intense driving scenarios.

Implementing ground effects is another effective strategy. By optimizing the underbody to create a low-pressure zone, designers can increase downforce without adding drag. Techniques like diffuser design allow the vehicle to effectively channel air, further enhancing grip and stability.

Finally, testing in wind tunnels remains a key component in fine-tuning designs. By simulating various conditions, engineers can observe the car’s performance and make data-driven adjustments. This hands-on testing leads to tangible improvements in real-world driving scenarios, ensuring that the innovations translate to superior performance on the road.

The Influence of Aerodynamic Testing on Supercar Development

Aerodynamic testing significantly enhances the performance and efficiency of supercars. Manufacturers apply simulations and wind tunnel testing to refine designs based on real data, optimizing performance attributes like downforce and drag.

Wind tunnels enable engineers to observe airflow patterns around prototypes, allowing them to make informed modifications. By adjusting elements such as spoilers, diffusers, and body shapes, developers can achieve an optimal balance between aerodynamic efficiency and aesthetic appeal.

Key factors influenced by aerodynamic testing include:

- Downforce: Increased downforce improves traction, enhancing cornering capabilities and stability at high speeds.

- Drag Reduction: Lower drag coefficients contribute to higher top speeds and improved fuel efficiency.

- Cooling Efficiency: Proper airflow directs cooling air to critical engine components, preventing overheating during performance drives.

Simulation software, like computational fluid dynamics (CFD), complements wind tunnel testing. This technology allows for in-depth analysis and rapid iteration of designs, saving time and resources. Engineers can test a variety of configurations without the constraints of physical prototypes, leading to innovative aerodynamic solutions.

Collaboration between designers and aerodynamicists is crucial. Regular communication enables the integration of aerodynamic insights into the design process from the outset, ensuring that performance goals align with visual objectives.

Manufacturers like Ferrari and McLaren have documented the impact of rigorous aerodynamic testing on their models. In the development of the McLaren P1, extensive simulations revealed design adjustments that enhanced both aesthetics and performance metrics, resulting in a car that not only looked fast but also maximized speed and handling.

In summary, aerodynamic testing plays a pivotal role in supercar development by providing actionable insights that guide design modifications, ultimately shaping vehicles that excel on both the road and track.

Real-World Examples of Aerodynamics in Supercar Racing

Supercars like the Ferrari 488 GTB utilize active aerodynamics, adjusting wing angles in real-time to optimize downforce during races. This adaptability allows drivers to enhance grip while navigating sharp corners, significantly reducing lap times.

The McLaren P1 leverages advanced aerodynamics with a focus on streamlined bodywork. Its design minimizes drag and maximizes airflow over key components, showcasing how aerodynamic efficiency can lead to dramatic performance improvements on the track.

In GT racing, the Porsche 911 GT3 R features an adjustable rear wing and a front splitter for precise aerodynamic tuning. These adjustments help the car maintain stability at high speeds, demonstrating how fine-tuning can yield competitive advantages in endurance racing.

Lamborghini’s Huracán GT3 employs a rear diffuser that increases downforce without adding excess drag. This design choice allows for higher speeds on straights while ensuring optimal cornering capabilities, showcasing a strategic balance between speed and grip.

Additionally, the Audi R8 LMS has developed unique aerodynamic features such as side skirts and a flat underbody that enhance airflow, improving overall handling. This example illustrates the combination of efficiency and control that well-designed aerodynamics can achieve.

Each of these supercars highlights not just the importance of aerodynamics, but also the need for constant innovation in racing technology to push performance boundaries. By studying these real-world applications, engineers continue to refine designs that enhance both speed and safety on the track.